Case Study 3 : Importance of Pressure Gauge

Why Pressure gauges are often found to be damaged or inaccurate?

Pressure, vacuum, and temperature gauges are essential and significant accessories in any pumping system, whether they are positioned at the suction or inlet, or at the discharge or outlet (located before the discharge valve) of a process or vacuum pump. These gauges play a crucial role in helping engineers, technicians, and operators gain a better understanding of the systems. They are particularly useful when troubleshooting various causes and issues. However, newly installed gauges are often discovered to be either damaged or inaccurate within a short period or when troubleshooting is required. This can pose challenges for engineers who may struggle to determine or conduct a proper analysis of the problems. Thus, gauges are very important instruments and should be replaced as soon as possible when damaged.

Pressure Gauges

Pressure Gauge: Bourdon Tube Type

Gauges are often prone to damage or inaccuracy. The Bourdon Tube, a crucial component of the inner mechanism, may become deformed or cracked. Some contributing factors may include:

- A sudden surge of pressure

- Constant Vibrations

- Extreme Temperature

- Affected by Chemicals

- Clogged by Slurry / Sludge / Debris

Bourdon Tube, source from (https://www.sciencedirect.com/topics/engineering/bourdon-gauge).

Compound Gauges

Compound gauges, which provide both positive and negative pressure readings, should be installed at the pump suction or inlet to determine the presence of static head or issues such as NPSH (Net Positive Suction Head).

Temperature Gauges

Emmecom Vacuum Gauges

Additional Gauge "Protection" that would extend the life-span

- Gauge Siphon

The coil at the Siphon acts as a liquid buffer zone. If high temperature steam enters the siphon, the measuring element will only be exposed to the cool buffer liquid. thus protecting the inner mechanism of the gauge.

Gauge Siphon, source from (https://www.as-schneider.com/gb/en/Products)

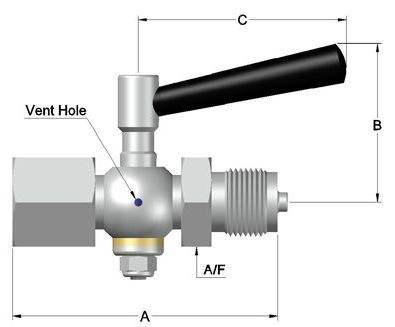

- Gauge Cock Valve (Lower Cost Option)

The gauge cock valve provides the opportunity to either vent the connected pressure gauge (venting position), pressurize the pressure gauge with supply pipe open (operating position) or to let the medium escape (blow position) according to the position of the handle. It is mainly used to isolate the process liquid from gauge to extend the life-span of gauge or protect the gauge. The gauge cock valve is opened to read the gauge and shut off after reading.

Gauge Cock Valve, source from (https://www.dawsonstech.com)

- Pressure Gauge Snubber

The Pressure gauge snubber able to snub or suppress the sudden surge of pressure, minimise the dampen pulsation and improve the accuracy.

Pressure Gauge Snubber, source from (https://www.ashcroft.com/products)

- Gauge Valve / Cock with Snubber (Higher Cost Option)

The gauge Valve is the combination of cock valve with snubber .

Gauge Valve, source from (https://www.racheprocess.com)

- Diaphragm Seals for Gauges (Best & Highest Cost Option)

Diaphragm seals are employed to protect the pressure-sensing assembly of differential, gauge, or absolute pressure transmitters from direct contact with the process medium. This protective measure prevents the pressure gauge from being exposed to potentially hazardous substances, such as extremely hot, viscous, or corrosive media, thereby significantly prolonging the instrument's lifespan.

Diaphragm Seal with Gauge , source from (https://www.ccgroup.com.tw)

Gauge Valve, source from (https://reotemp.com/products)

Gauge Adaptors & Fittings

Example: 1/2" male fit to 1/4" female in order to suit a 1/4" Gauge Connection.

Pressure Gauges

Pressure Gauges