Case Study 1: Severe Vibration on Pump

Problem Statement of Case Study 1

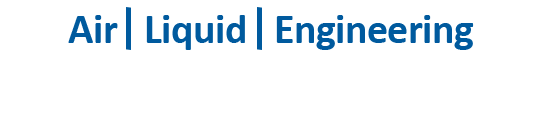

The issue at hand concerns severe vibration experienced by the pumps while operating, which persists until the unit are shut down. Those pumps with high vibration are the VS-4 type vertical sump pumps and they are fabricated with extended shafts of 2 meters in length. According to the pump's nameplate, it is designed to deliver a rated flow of 10.8 m3/h at a head of 22 meters. Unfortunately, those pumps had experienced a breakdown after 6 months of operation.

Keywords:

- Pump vibration

- No discharge valve and pressure gauge

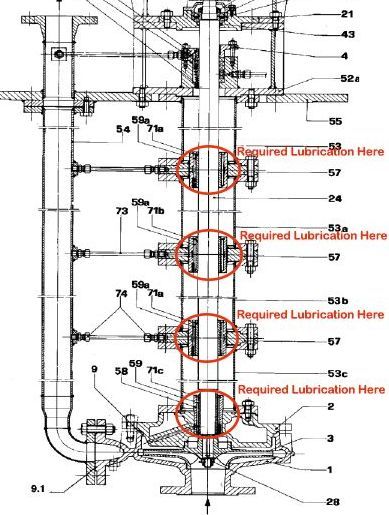

- No lubrication for sleeve bearing

- Beyond maximum allowable flow

- Dry running

Pump's nameplate

Findings of Problems

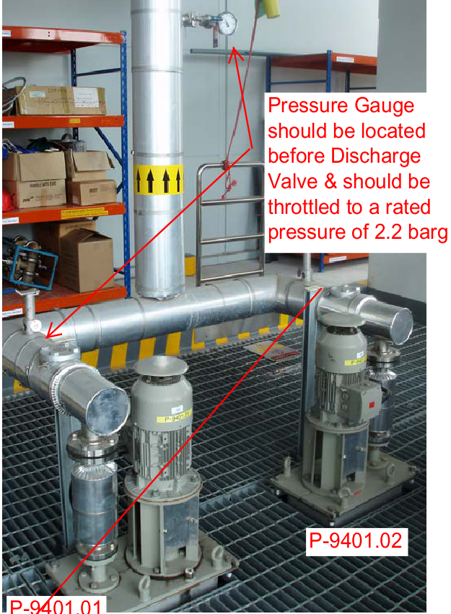

- There are no Discharge Valves for both Pumps.

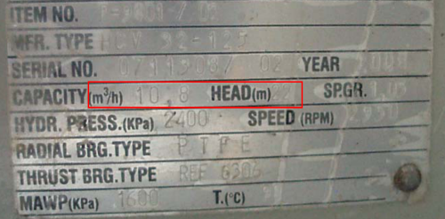

In a well-executed pump installation/layout, it is essential to incorporate throttle valves in the pump's discharge lines. This measure ensures the regulation of pressure to match the specified or rated pressure outlined in the pump curve. As there are no discharge valves, the following issue occurs:

Pump Performance Curve

- Pumps were operating beyond the maximum allowable flow rate.

In the absence of a control/discharge valve, the pump tends to operate to the right side of the curve, as the specific pumps were found to be operating at 1.3 bar (g) instead of the designated pressure of 2.2 bar (g) (refer to the curve below), the 1.3 bar (g) shows a higher flow of 18 m3/h instead of 10.8 m3/h (rated flow). As the pump operates beyond the maximum allowable flow, the operating ampere exceeds the Non-overloading Limit (NOL), resulting in high amperage. Consequently, the pump experiences severe cavitation and vibration, ultimately leading to premature failure.

- Dry running

The level of liquid in the sump is lower than the minimum required level. Thus, dry running occurs. The sleeve bearing for one of the pumps is damaged as it may be subjected to dry running. Dry running should not be allowed even for a short period as the sleeve bearings require constant lubrication from the pumped media.

Sleeve Bearing Lubrication

- Pressure Gauge Installation

The gauge should be located between the Pump Flange and the Discharge Valve in order to read the Operating Pressure of the pump.

Installation of 2 units VS-4 Vertical Sump Pump